| –

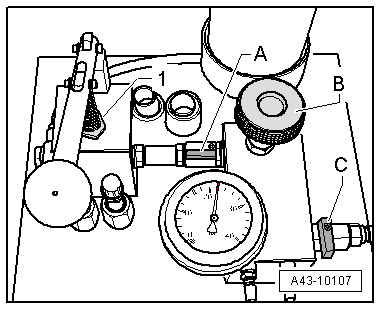

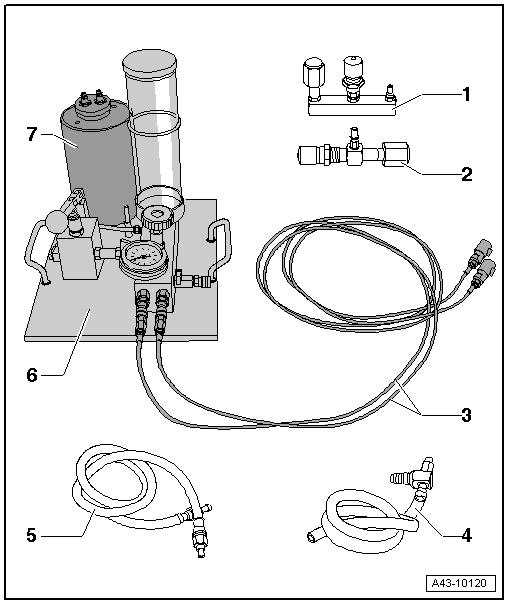

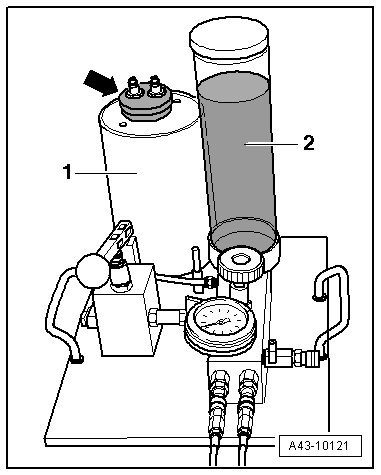

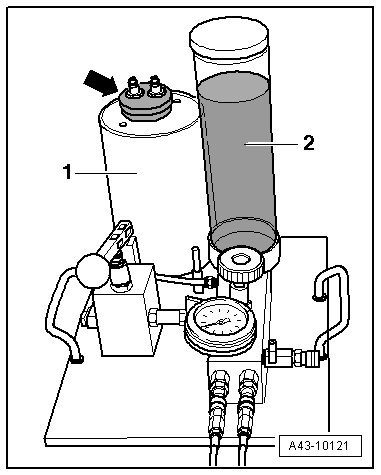

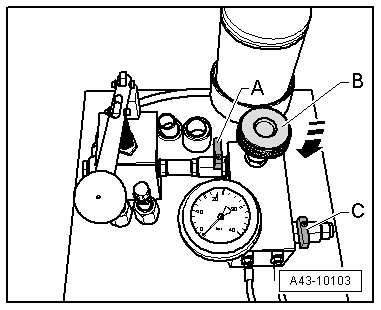

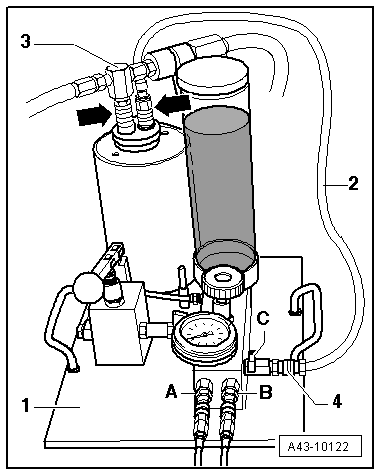

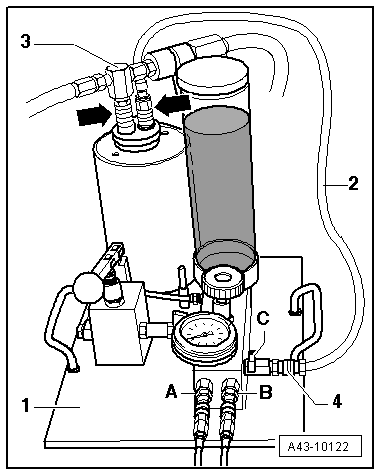

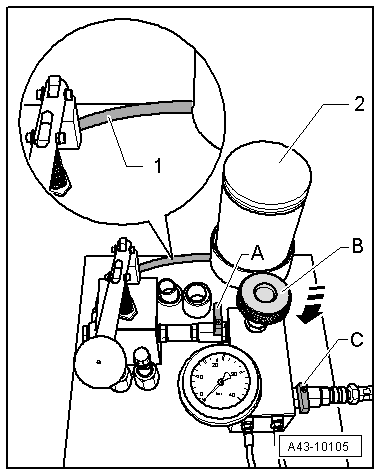

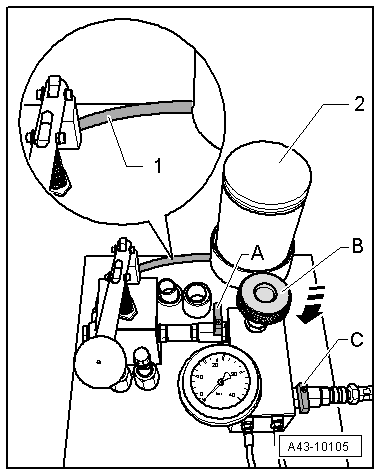

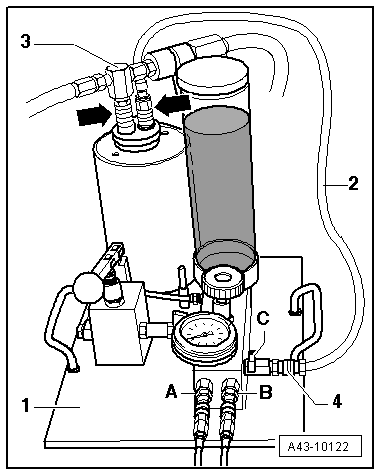

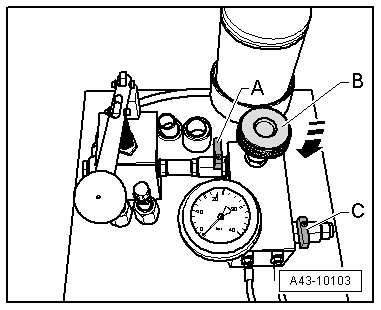

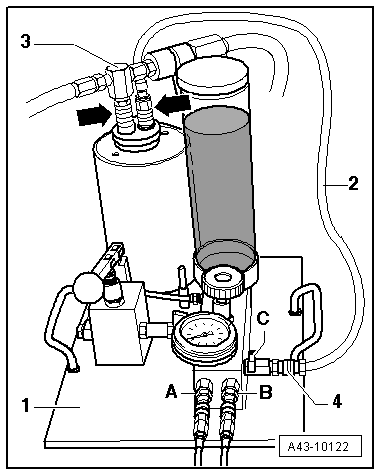

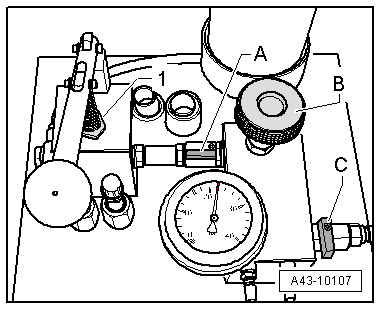

| Open valve -A- and charge DRC system to 22 bar by repeatedly pumping lever of hand-operated pump -1-. |

Note | Make sure the fluid container of the filling device for DRC system -VAS 6544- does not run empty when charging. Top up the fluid container with fresh fluid if necessary. |

| l

| When a pressure of 22 bar has been reached, close valve -A- and stop pumping lever of hand-operated pump. |

Note | t

| The quality of the filling process is not improved if the maximum pressure of 22 bar is exceeded. Caution: this can damage the DRC system components and filling device for DRC system -VAS 6544-! |

| t

| If the pressure of 22 bar cannot be reached, or if the pressure drops continuously, check all the separating couplings and connections for leaks and damage. If no irregularities are visible on the outside, the piston of the gas accumulator inside the central valve leading to the pressure chambers is leaking, so the central valve must be renewed. |

| –

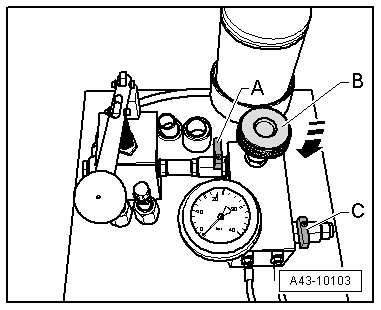

| Open needle valve -B- slightly and allow pressure to drop to 20 bar. |

| l

| When needle on pressure gauge reaches 20 bar mark, close valve -B-. |

Note | On some versions of the pressure gauge, the 16 bar graduation has a green marking. This marking is irrelevant to the application described here and must be ignored. |

| Charging of the DRC system is now completed. |

| –

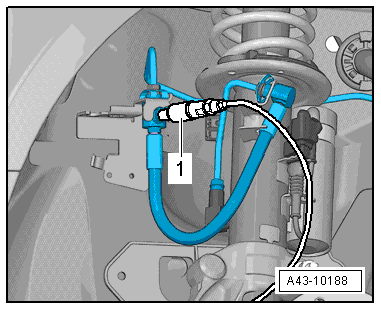

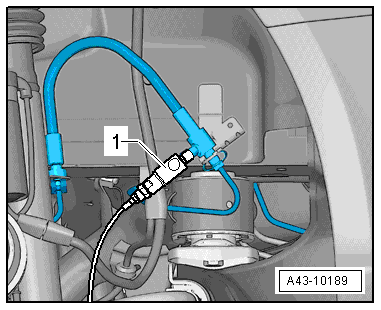

| Disconnect charging line with quick-release coupling of filling device for DRC system -VAS 6544- → Item from drain/charge valves (front and rear). |

| –

| Screw on dust cap for drain/charge valves (front and rear). |

|

|

|

Note

Note Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Caution

Caution WARNING

WARNING